- +1 281.389.0771

- info@olgess.net

-

Mon - Fri: 8:00 - 17:00 / Closed on Weekends

IMPLEMENTATION

.

.

REGULATION OF OIL AND GAS WASTES

The Railroad Commission has jurisdiction over oil and gas wastes, which

include all wastes generated in association with the following activities:

■

drilling, operation, and plugging of wells associated with the exploration,

development, or production of oil and gas. This includes oil and gas wells,

fluid injection wells, and disposal wells; ■

separation and treatment of produced fluids in the field or at natural gas

processing plants;storage of crude oil before it enters a refinery;

■

underground storage of hydrocarbons and natural gas; transportation of crude

oil or natural gas by pipeline; ■

solution mining of brine; and ■

storage, hauling, disposal, or reclamation of wastes generated by these

activities. The Railroad Commission regulates all oil and gas waste in

Texas, both hazardous and nonhazardous. Statewide Rule 30, Memorandum of

Understanding Between the Railroad Commission of Texas (RRC) and the Texas

Commission on Environmental Quality (TCEQ), provides additional guidance

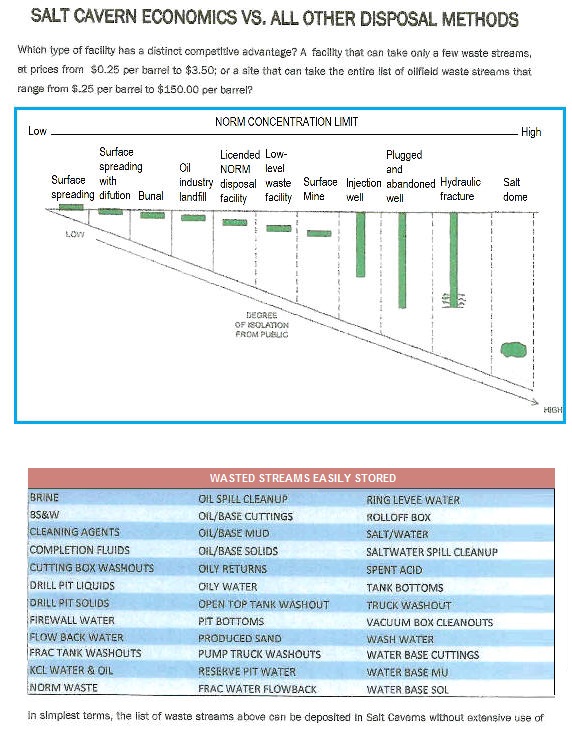

for determining jurisdiction over waste in Texas. The public is safest when

salt caverns are utilized for waste disposal. There is a certain scarcity of

salt caverns that are available for oilfield waste storage.

HAYNESVILLE SHALE ACTIVITY

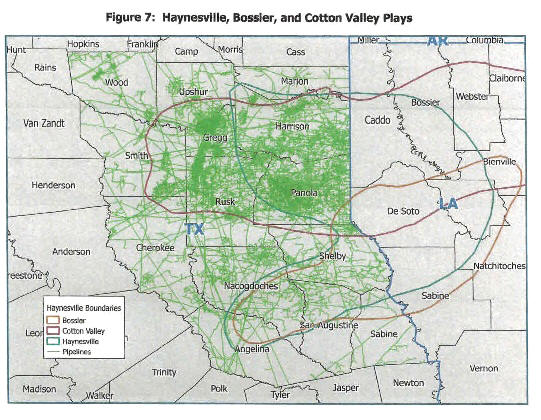

The Haynesslile Shale is active, has very well developed Infrastructure, is profltable today, and is estimated to have as many as 35,000 new drilling locations. At current drilling rates, this activity could last for decades into the future. There Is plenty of future work here.

Haynesville gas production Is surging Into the new year, climbing to its highest in nearly eight months, as operators there respond to a bullish outlook for the basin's strategically located supply.

In January, Haynesville production gas averaged over 13 Bcf/d as a wave of new rig additions lifts the basin's total to its highest since January 2020, data compiled by S&P Global Plans Analytics shows. In the fourth quarter, operators In the Texas-Louisiana shale play added 10 rigs, bringing the total fleet to 46 as of Dec. 30 currently according to data published by Enverus. Following the fallout in commodity prices last March, the Haynesville is now the only major US shale basin to have fully recovered Its drilling fleet.

GROWTH DRIVERS FOR THE SALT CAVERN LOCATION

1. Growth Drivers

■ East Texas Market Growth:

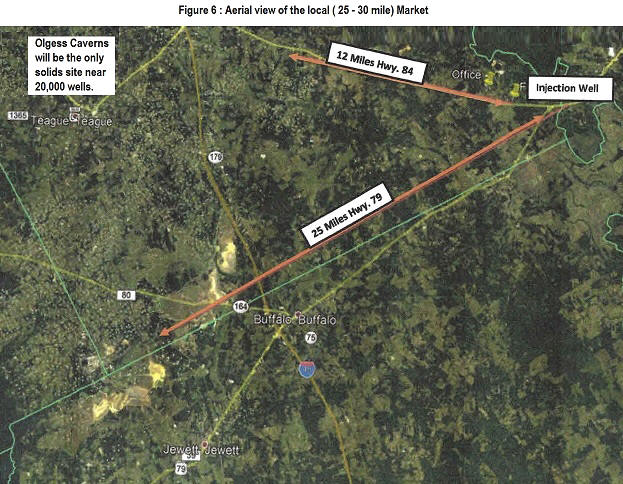

■ The number of existing oil and gas wells in Freestone and the surrounding counties measures more than 26,900. The number of drilling rigs running In the U.S. Is 484 with half of those rigs operating in Texas.* July rigs in Texas District 6 averaged 17 rigs running with 18 rigs running In Northern Louisiana.

■ The quality and financial strength of E & P companies newly In the East Texas Region targeting the gassy Haynesvllle Shale, the Woodbine (conventional), the Eaglebine, the Cotton Valley, Buda, and various shales in Western Louisiana mean that drilling will continue. Breakeven costs In the Haynesvlll Shale have fallen to $2.30 to $2.40/MMBtu, making these wells highly profitable.

*Sources: Baker Hughes, Department of Energy.

■ The Principals of Olgess are known operators and vendors of services to many of these larger, financially capable operators. The Company will institute operating and safety procedures that are critical to larger companies who are extremely liability conscious.

■ The site's proximity to the Barnett shale in Texas and the Haynesvllle shale in Louisiana is ideal as both shale plays have shown a tendency to produce large quantities of Naturally Occurring Radioactive Waste (NORM).

■ Significant NORM disposal opportunities are present in the region with little competition. NORM is present in many of the older oil and gas fields alongthe Gulf Coast. As a result, the presence of NORM in these fields is almost a certainty. The Barnett shale began experiencing NORM build-up In as few as 5 years of production. Principals of Olgess have dealt with disposal of produced saltwater, completion fluids, drilling mud and cuttings, sale of skim oil and disposal of NORM. NORM occurs as an accumulation of scale in pipelines, tank batteries and field equipment. Argonne Labs, worklng for the Energy Information Administration (EIA), has estimated that in 1995 there were in excess of 10,000,000 barrels of NORM that require disposal In the U.S. Additionally, 140,000 barrels are being added to the total annual'. At $100.00+ per barrel, for disposal, 10,000,000 barrels of NORM represent a $1 Billion market with $140 million new NORM barrels being generated each year. The Argonne study was done in 1995. Drilling has picked up precipitously since 2000 with large numbers of new wells per year, further expanding the growth of produced water and NORM.

■ Capacity: The Olgess disposal well site carries a permit to dispose of 15,000 Barrels of Produced and Frac water per day. The permit from the Texas Railroad Commission includes the right to inject at a pressure of up to 2,995 pounds. This gives Olgess the capacity to build a business that can grow considerably from several sources: water base drilling mud, oil base drilling mud, completion fluids, produced water, and NORM.

-

■ Pricing: Pricing In the region Is believed to be $.40 per barrel for produced saltwater and $.75 for

spent frac fluids. Pricing trends are improving and the capacity for disposal in the region is sized to serve a market that has been growing at a much slower pace for the last decade.

■ Legacy Wells from Prior Drilling Booms: The area within 150 miles of the site was heavily drilled In the Austin Chalk, Haynesville Shale, Barnett Shale, Rhodessa, and Cotton Valley plays in the early 2000's by major oil producers. These wells must be re-worked, re-completed, and are subject to replacement of all downhole tubing and equipment on a periodic basis. This makes for a plethora of remedial work that generates consistent revenue to a Cavern Company as re-completion fluids, chemicals, and scale from tubing (often laden with NORM) is removed.

■ The Principals of Olgess are known operators and vendor of services to many of these larger, financially capable operators. The Company will Institute operating and safety procedures that are critical to larger companies who are extremely liability conscious.

■ The site's proximity to the Barnett shale in Texas and the Haynesvlfle shale in Louisiana Is ideal as both shale plays have shown a tendency to produce large quantities of Naturally Occurring Radioactive Waste (NORM).

2. Value In Expanding Olgess's Permited Wastes to Include NORM -The Company will commence marketing with a broad, professional, marketing effort to bring in larger customers and add additional sites to extend its services to new areas. NORM is sensitive Issue for oil & gas companies. Disposal of NORM in salt caverns is considered the optimal solution by Federal Regulators. (see Appendix II)

- ■ NORM revenue per barrel can be as much as 20 x the revenue per barrel generated by drilling mud and cuttings, and disposing of it is not so different. The added burden is largely born by the Radiation Safety Officer.

- ■ Olgess's existing site is a first step for re-entering the disposal arena in an area that is bereft of solids and NORM disposal locations.

- ■ E & P companies decreasing vendor lists. As a trusted vendor for disposal of NORM, the Company's personnel will pass the practices and procedures criteria that are most important to these larger, risk averse, producers with their most politically sensitive disposal product. This should give our site a marketing advantage vs. competitors in the region. The client wants a professional, environmentally aware, partner to handle its disposal needs and reduce contingent liabilities.

3. Strategic Relationship with Existing Oilfield Fluids Transportation Company.

- ■ The Company has a strategic relationship with several transportation companies in the region. These companies will provide quick sources of revenue from the 1st month of operation. It will also allow us to co-market our services as a means of simplifying the accounting function for waste disposal on a well-by-well basis, another initiative voiced by larger E & P clients.

4. Competition/Barriers to Entry. Due to the nature of the commercial disposal well process, the Company will have a lead during the critical ramp-up phase of operations for this region. This lead time will allow us to establish ourselves as the operator in the region using best practices and procedures in the industry.

■ Our entry Into the market will discourage new participants from locating within 40 miles unless our site is fully loaded and unable to take on more waste streams.

■ Olgess personnel have had accounts with over 240 oil & gas customers in the past, including many established leading companies In the oil and gas industry. We will be a natural fit for most operators in the region.

5. Expansion. Vertical and Lateral integration

Olgess's management team has mapped a strategy to expand its footprint in East Texas. This includes adding trucking capability for NORM and Drilling Mud and Cuttings. We expect to add services in three separate steps over a one-year time frame:

Stage 1 - Produced water and frac water (existing commercial well can accept both)

Stage 2 - Permitting a cavern to accept drilling mud and solids (permitting is straightforward)

Stage 3 - Adding NORM disposal and ultimately decontamination of equipment that is NORM contaminated. (This will be implemented subject to receipt of permits and licenses)

Stage 4 - Solution mining additional cavern space on the 177 acres for purposes of providing storage for more waste as the existing caverns fill.

NORM AND TENORM WASTE

NATURALLY OCCURING RADIOACTIVE WASTE IN OIL SHALES (NORM & TENORM)

Oil and gas TENORM and/or NORM is created in the production process, when produced fluids from reservoirs carry sulfates up to the surface of the Earth's crust. Some states, such as North Dakota, uses the term "diffuse NORM". Barium, calcium and strontium sulfates are larger compounds, and the smaller atoms, such as radium‑226 and radium-228, can fit into the empty spaces of the compound and be carried through the produced fluids. As the fluids approach the surface, changes in the temperature and pressure cause the barium, calcium, strontium and radium sulfates to precipitate out of solution and form scale on the inside, or on occasion, the outside of the tubulars and/or casing. The use of tubulars in the production process that are NORM contaminated does not cause a health hazard if the scale is inside the tubulars and the tubulars remain down hole. Enhanced concentrations of the radium 226 and 228 and the daughter products such as lead-210 may also occur in sludge that accumulates in oilfield pits, tanks and lagoons. Radon gas in the natural gas streams concentrate as NORM in gas processing activities. Radon decays to lead-210, then to bismuth-210, polonium-210 and stabilizes with lead-2. Radon decay elements occur as a shiny film on the inner surface of inlet lines, treating units, pumps and valves associated with propylene, ethane and propane processing systems. Disposal of more concentrated wastes requires greater isolation of waste from the general public.

NORM characteristics vary depending on the nature of the waste. NORM may be created in a crystalline form, which is brittle and thin, and can cause flaking to occur in tubulars. NORM formed in carbonate matrix can have a density of 3.5 grams/cubic centimeters and must be noted when packing for transportation. NORM scales may be white or a brown solid, or thick sludge to solid, dry flaky substances.

Cutting and reaming oilfield pipe, removing solids from tanks and pits, and refurbishing gas processing equipment may expose employees to particles containing increased levels of alpha emitting radionuclides that could pose health risks if inhaled or ingested. The hazards associated with NORM are inhalation and ingestion routes of entry as well as external exposure where there has been a significant accumulation of scales. Respirators may be necessary in dry processes, where NORM scales and dust become air borne and have a significant chance to enter the body.

The hazardous elements found in NORM are radium 226, 228 and radon 222 and daughter products from these radionuclides. The elements are referred to as "bone seekers" which when inside the body migrate to the bone tissue and concentrate. This exposure can cause bone cancers and other bone abnormalities. The concentration of radium and other daughter products build overtime, with several years of excessive exposures. Therefore, from a liability standpoint an employee that has not had respiratory protection over several years could develop bone or other cancers from NORM exposure and decide to seek compensation such as medical expenses and lost wages from the oil company which generated the TENORM and the employer.

Radium radionuclides emit alpha and beta particles as well as gamma rays. The radiation emitted from a radium 226 atom is 96% alpha particles and 4% gamma rays. The alpha carticle Is not the most dangerous particle associated with NORM. Alpha particles are identical with helium-4 nuclei. Alpha particles travel short distances In air, of only 2-3 cm, and cannot penetrate through a dead layer of skin on the human body. However, some radium alpha particle emitters are bone seekers due to radium possessing a high affinity for chloride ions. In the case that radium atoms are not expelled from the body, they concentrate in areas where chloride Ions are prevalent, such as bone tissue. The half-life for radium 226 is approximately 1,620 years and will remain In the body for the lifetime of the human - a significant length of time to cause damage.

Beta carticles are high energy electrons or positrons. They are in the middle of the scale in terms of ionizing potential and penetrating power, being stopped by a few millimeters of plastic. This radiation is a small portion of the total emitted during radium 226 decay. Radium 228 emits beta particles and is also a concern for human health through inhalation and ingestion. Beta particles are electrons or positrons and can travel farther than alpha particles In air.

The gamma rays emitted from radium 226, accounting for 4% of the radiation, are harmful to humans with sufficient exposure. Gamma rays are highly penetrating and some can pass through metals, so Geiger counters or a scintillation probe are used to measure gamma ray exposures when monitoring for NORM.

Alpha and beta particles are harmful once inside the body. Breathing NORM contaminates from dusts should be prevented by wearing respirators with particulate filters. In the case of properly trained occupational NORM workers, air monitoring and analysis may be necessary. These measurements, ALl and DAC, are calculated values based on the dose an average employee working 2,000 hours a year may be exposed to. The current legal limit exposure in the United States is I AU, or 5 rems. A rem, or Roentgen equivalent man, is a measurement of absorption of radiation on parts of the body over an extended period of time. A DAC is a concentration of alpha and beta particles that an average working employee Is exposed to for 2,000 hours of light work. If an employee is exposed to over 10% of an ALl. 500 mREM, then the employee's dose must be documented under Instructions with federal and state regulations.

Radioactive-Waste Disposal: TEXAS COMMISSION ON ENVIRONMENTAL QUALITY: NORM Disposal *

*Texas Commission on Environmental Quality April 2018

Radioactive-Waste Disposal: NORM Disposal. Defines "naturally occurring radioactive material" and links to TCEQ rules and guidance relevant to the disposal in Texas of wastes that contain these materials.

WHY SHOULD WE CARE ABOUT NORM WASTES?

In general, NORM wastes contain radionuclides found in nature, such as radium, thorium, or uranium. Once these radionuclides become concentrated through human activity, they can become radioactive hazards through potential ingestion or by direct exposure from radiation the material emits. Some NORMs are heavy metals and are themselves toxic, for example, uranium. Radium-226 Is of concern because it decays to the radioactive gas radon. Radon has been shown, at high concentrations, to increase the risk of cancer in the lungs of persons who regularly breathe it.

WHO REGULATES NORM IN TEXAS?

NORM was not subject to regulatory control under the Atomic Energy Act of 1954 or the Low Level Radioactive Waste Policy Act. Thus, NORM was subject primarily to individual state radiation-control regulations. Section 651(e) of the Energy Policy Act of 2005 gives the NRC jurisdiction over discrete sources of NORM by redefining the definition of source material.

In Texas, NORM is regulated under the Texas Radiation Control Act as follows:

■ The Texas Departmentof State Health Services (DSHS). Radiation Control has jurisdiction over the use, treatment and storage of NORM (DSHS NORM Licensing Web Page).

■ The Railroad Commssion of Texas has jurisdiction over the handling and disposal of NORM wastes produced during the exploration and production of oil and gas (RRC rules for NORM).

■ The TCEQ has jurisdiction over the disposal of low level radioactive wastes generated outside the E & P Industry.

What Are the Legal Requirements Governing Disposal of Oil Field Wastes into Salt Caverns? The Underground Injection Control (UIC) program, under the Safe Drinking Water Washington, DC Act, is a federal program that governs disposal of oil field wastes into salt caverns. Wells into which wastes and other fluids are injected are considered to be UIC wells. Injection wells used for disposal of oil field wastes are called Class II injection wells. Many state oil and gas agencies have assumed the authority from EPA to administer Class II injection well programs. These agencies develop state regulations and Issue permits or other authorizations for oil field waste disposal. Texas, New Mexico, and Louisiana are currently developing regulations that will specifically govern disposal of oil field wastes Into caverns. An Introduction to Salt Caverns & Their Use for Disposal of Oil Field Wastes. State agencies have the lead responsibility for managing oil field wastes. The federal law covering waste management is the Resource Conservation and Recovery Act (RCRA). Under provisions of RCRA the U.S. Environmental Protection Agency (EPA) establishes regulations to manage hazardous wastes. In 1988, EPA announced that wastes resulting from exploration and production of oil and gas were exempted from the hazardous waste requirements of RCRA. In other words, these wastes were considered to be nonhazardous. EPA concluded that existing state regulatory programs were generally adequate to control oil field wastes. Since 1988, state waste management programs have been strengthened. (All state oil and gas agencies have NOW management requirements, and several oil producing states also have NORM management requirements).

CONCLUSION

Proper planning and aggressively seeking bids allows the team to maintain costs and hit Capital Expenditure estimates. The existing market for NOW muds is attractive and competition is sparse, with the exception being multiple competitors for frac flowback and produced water.

Existing Cavern space will provide for an estimated 2 to 5 years of cavern disposal due to the fact that excess liquids will be sent to the disposal well. This is critical to preserving cavern space for high margin products like drilling mud, cuttings, and NORM.

New Cavern construction will be required in the future but will be the result of success in the solids and NORM disposal which are highly profitable. The market for NORM disposal is an extremely attractive niche for the cornpany to fill. Major Oil & Gas companies associate all waste disposal with liability. As such, all things being equal, a cavern site for disposal lessens the perceived liability of those companies.

If 3rd party waste haulers are reluctant, slow, or not inclined to include the facility as drop off points, then trucking can be added for purposes of serving the drilling mud and cuttings market and the NORM market

Key variables to obtain new business

1. For Larger customer companies, Safety. Practices and Procedures, and reliability

2. For medium size E & P customers - Reliability, price, and proximity

3. For smaller E & P customers - Proximity, price, and reliability

4. For Trucking companies that direct waste streams - Proximity, speed of offloading and price

5. Most E & P companies, from time to time, need our record keeping substantiating their own when dealing with the Railroad Commission. it matters.

i

https://www.energy.gov/fe/services/petroleum-reserves/strategic-petroleum-reserve/spr-storage-sites

ii Salt Caverns & Their Use for Disposal of Oil Field Wastes

iii SUSTAINABLE ENERGY: How compressing air in underground salt caverns

could help the planet's shift to renewable energy. PUBLISHED FRI, JUN 7 2019

1:42 AM

iv Argonne National Laboratory for the U.S. Department of Energy, National

Petroleum Technology Office, Under Contract W-31-109-Eng-38. An Introduction

to Salt Caverns & Their Use for Disposal of Oil Field Wastes"